Frankengrinder

While changing the gears on my Hobbymat MD65 lathe, I discovered that I was missing a crucial accessory: a small bushing which in my French manual is affectionately called “le coussinet”. To add insult to injury, the manual continues to mention that this is an “accessoire normal”. I guess the lathe didn’t come complete with all accessories when I bought it second-hand. So I had to make my own replacement bushing. Fabricating a small bushing isn’t a big effort when one has a lathe, except that the bushing has a longitudinal slot which accepts a piece of 4x4mm square bar. Without a mill it wouldn’t be easy to machine this slot accurately, but I decided to get creative nonetheless.

While changing the gears on my Hobbymat MD65 lathe, I discovered that I was missing a crucial accessory: a small bushing which in my French manual is affectionately called “le coussinet”. To add insult to injury, the manual continues to mention that this is an “accessoire normal”. I guess the lathe didn’t come complete with all accessories when I bought it second-hand. So I had to make my own replacement bushing. Fabricating a small bushing isn’t a big effort when one has a lathe, except that the bushing has a longitudinal slot which accepts a piece of 4x4mm square bar. Without a mill it wouldn’t be easy to machine this slot accurately, but I decided to get creative nonetheless.

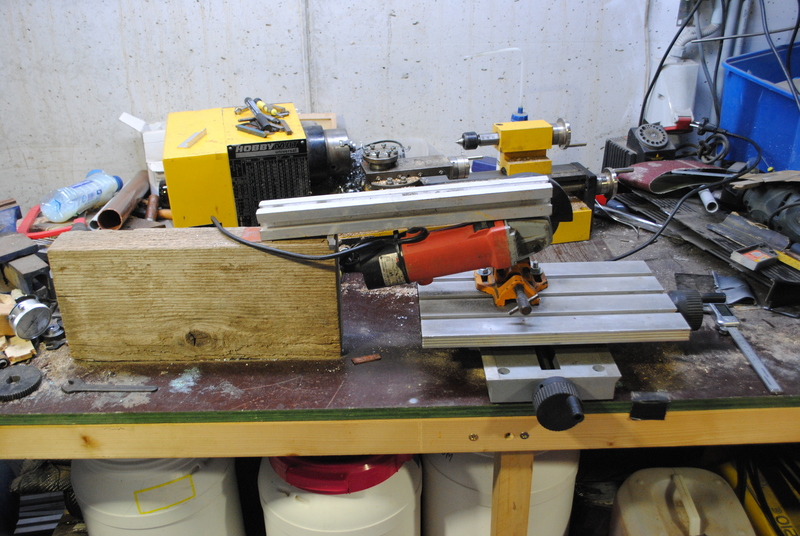

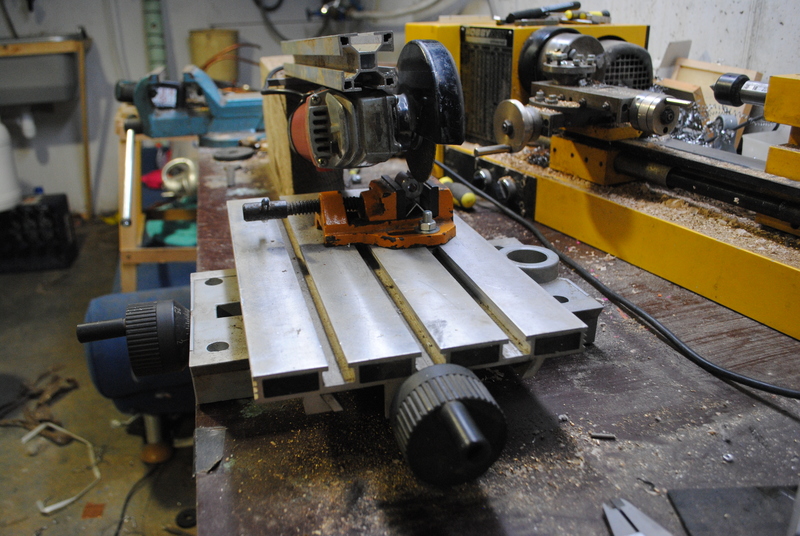

This is what I came up with. I decided to mount my blank on my spare X-Y positioning table, and grind the slot with a thin metal cut-off blade on my grinder.

I can’t begin to describe all the things that are wrong with this idea. Like how the aluminium extrusion locks the grinder’s power switch in the on position, which means I had to control the grinder using the power plug. Or the cantilever arrangement of mounting the grinder, causing vibration and movement in every direction and making cut depth adjustment pretty hard. But in the end it got the job done, and reasonably well if I may add!

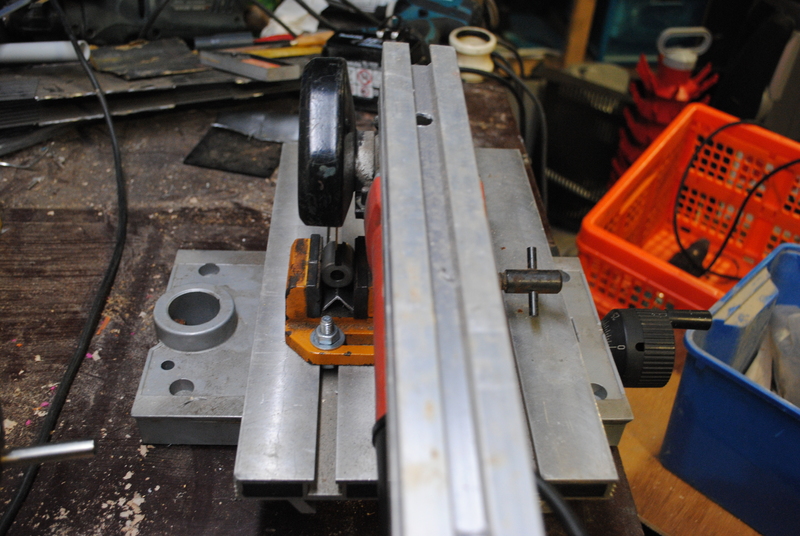

The grinder is mounted to a piece of alu extrusion, which is fixed to a scrap piece of construction lumber. A small metal bar under the cantilever point sets the cutting depth of the grinding disc.

The positioning table is used to move the blank into the disc length-wise, and to control the slot’s width.

This is a 70 Z gear mounted onto the original bushing:

And this is the same gear mounted on my homemade bushing:

I would say the result turned out pretty well.